Polymer Services Frequency Asked Questions

Here you can browse answers to common questions about engineered polymers and services.

Polymer Services Frequency Asked Questions

1. How do I identify key application requirements?

How do I identify key application requirements?

Taking the time to really understand things such as performance requirements, industry nuances, and regulatory demands provides vital insight into which material or design will bring your end-product vision to life.

Performance Requirements

Defining the expectations of the final product and the parameters around development is important to ensure success. Product use cases are critical to ensure such things as:

- Colors will last through long-term outdoor exposure

- The product doesn’t break from temperature fluctuations, exposure to moisture, or impact/drops

- If the product does break, it breaks in a preferred way (i.e., brittle vs ductile failure) to minimize user harm or further product damage

- Scratch & mar performance, wear resistance, and abrasion resistance minimize the appearance of wear and tear through normal user interaction

- Materials do not degrade when exposed to chemicals

Taking this a step further and considering end-of-life (reclaiming) goals may also influence design and material selection to align with your sustainability goals.

Industry Nuances

Every industry has a history and expectation of how things are done. Understanding the materials typically used in a particular industry or application provides context to then explore material alternatives and manufacturing methods. It also provides context on development timelines, some industries have tight timelines based on annual launch windows while others have a long specification process.

Regulatory / Compliance Demands

Ensuring you have approved material for your application use case is critical. Navigating approvals and, let’s be honest, paperwork can be overwhelming. Demands and requirements may vary by region and/or industry, so be sure to lean on the material expertise of your supplier to support you in meeting stringent requirements, such as those found in healthcare and food packaging. Some common requirements for which documentation or additional expertise during development can help include:

- UL

- USP Class VI

- ISO 10993

- REACH

- RoHS

2. How do I choose the right plastic for my application?

How do I choose the right plastic for my application?

Ensuring your material holds up in all use cases of your end application and meets performance expectations is complex. Sorting through countless material options can be even more daunting. Working with an experienced material supplier provides the combined benefit of in-depth material science knowledge and plastics processing insight to help you make an informed decision about which plastic is right for your application.

For example, specialized and sustainable polymer formulations may also be available, as well as colorants and additives to enhance performance or aesthetics, to enable proper material selection for each application’s unique requirements.

There are a number of things to consider when selecting the right material. Below are just a few considerations.

Thermoset vs Thermoplastic (What’s the difference?)

Thermoset materials are chemically cross-linked and cannot be reprocessed or recycled. Once the material is cured it is permanently rigid. Common examples are epoxy, silicone, and polyurethane (PU). Thermoplastic materials are not molecularly cross-linked and can be reprocessed or recycled. Reheating softens the material allowing it to be reshaped before becoming rigid once cooled. Common examples are polypropylene (PP), nylon (PA), polyketone (PK), and thermoplastic elastomers (TPE). Thermoset materials perform better in applications that require a harder material with higher temperature resistance. Thermoplastics are ideal for applications with less extreme temperature requirements and support sustainability initiatives since it can be reprocessed after molding.

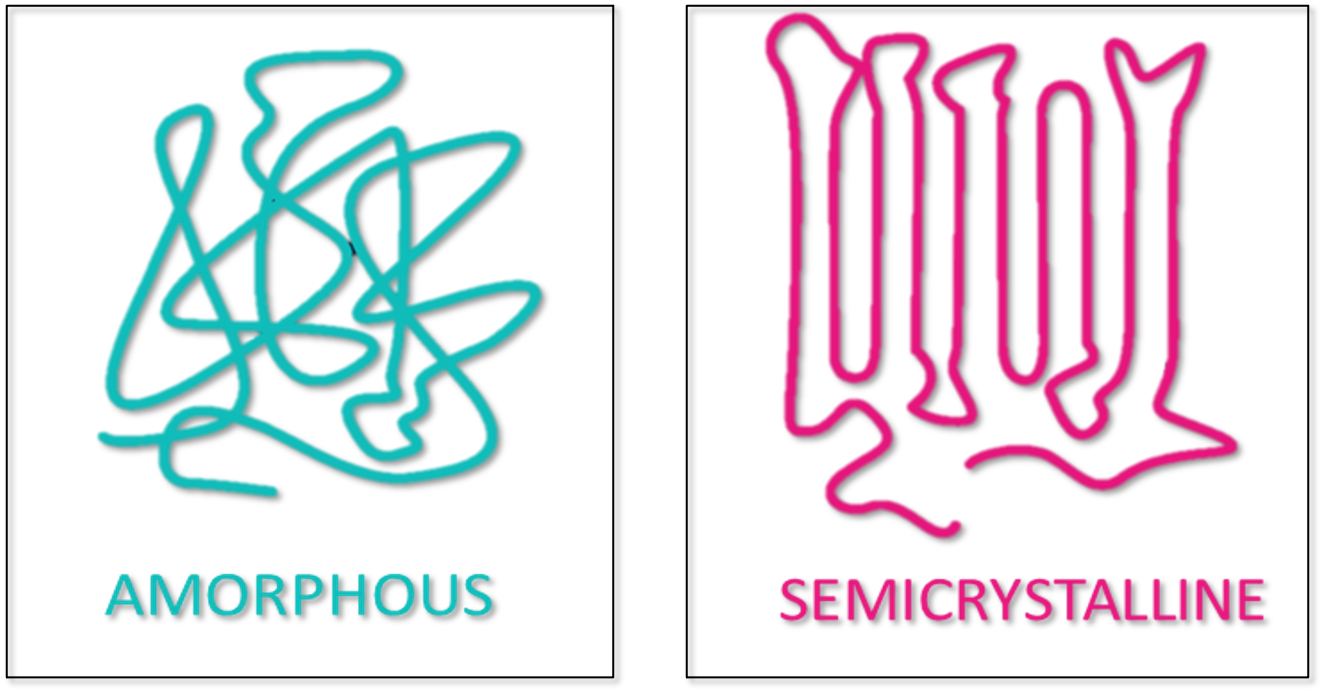

Amorphous vs Semi-Crystalline Thermoplastics

An amorphous thermoplastic material has no specific molecular structure while a semi-crystalline polymer has some order.

Examples of amorphous polymers are acrylonitrile butadiene styrene/acrylonitrile styrene acrylate (ABS/ASA), polycarbonate (PC), polymethyl methacrylate (PMMA), and copolyesters. These materials are typically transparent, with good impact strength, a glossy surface finish, and less warpage than semi-crystalline materials. The fatigue resistance, wear performance, chemical resistance, and sensitivity to stress cracking are considered poor. However, properties can be modified with fillers and/or additives.

Examples of semi-crystalline polymers are PP, polyethylene (PE), PA6, PA66, polyphthalamide (PPA), polybutylene/polyethylene terephthalate (PBT/PET), polyoxymethylene (POM) or acetal, polyphenylene sulfide (PPS), and polyether ether ketone (PEEK). These materials are typically opaque, with a sharp melting point, have good strength, excellent wear performance, and good chemical resistance. The impact strength, surface finish and warpage are not inherently good. However, properties can be modified easily with fillers and/or additives.

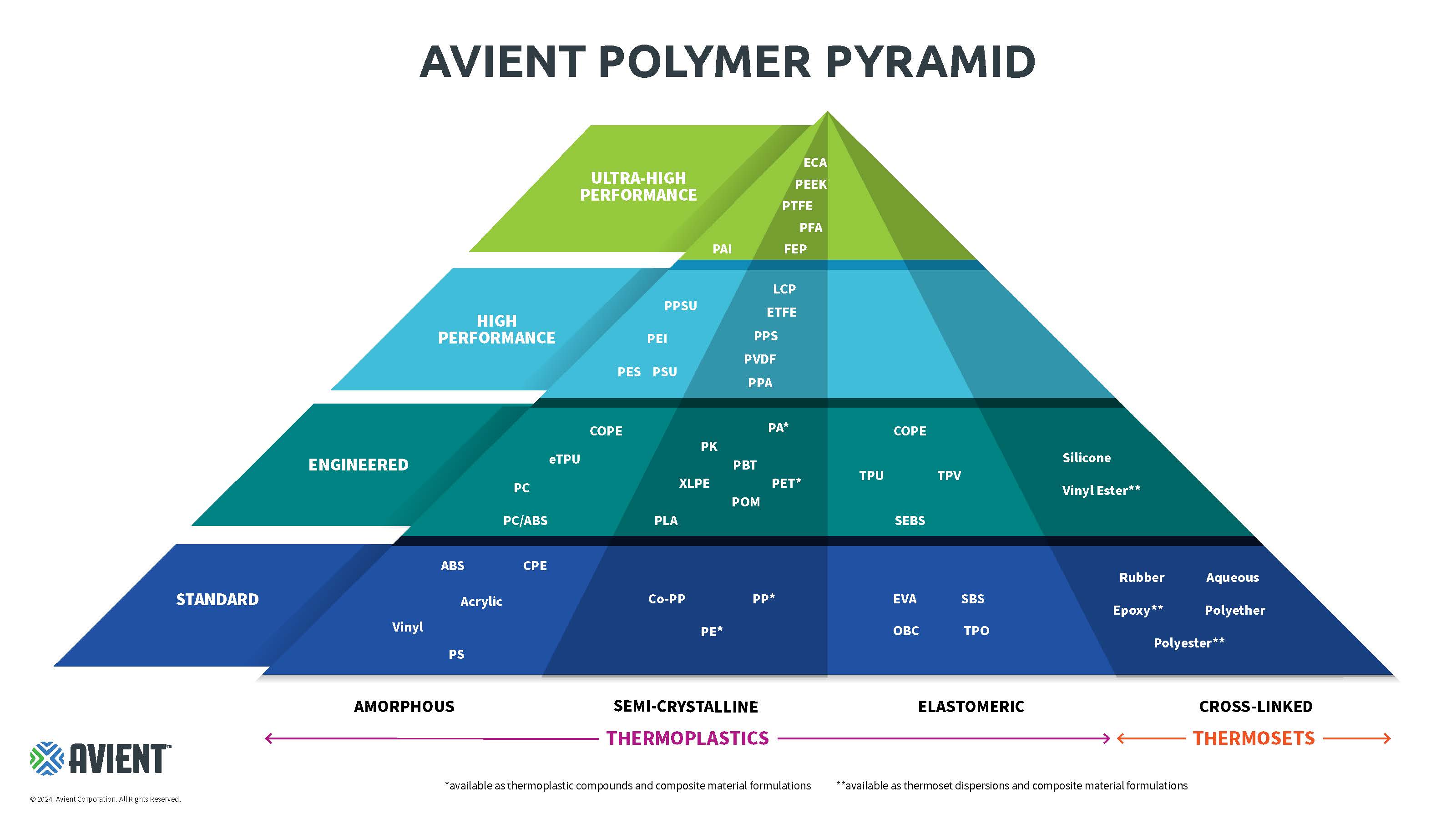

Polymer Pyramid - Base Resins

There are a number of polymers available to use as is or to be used to develop specialty materials. Your materials supplier can consult with your product development team to select the right material to meet your performance requirements and end product goals.

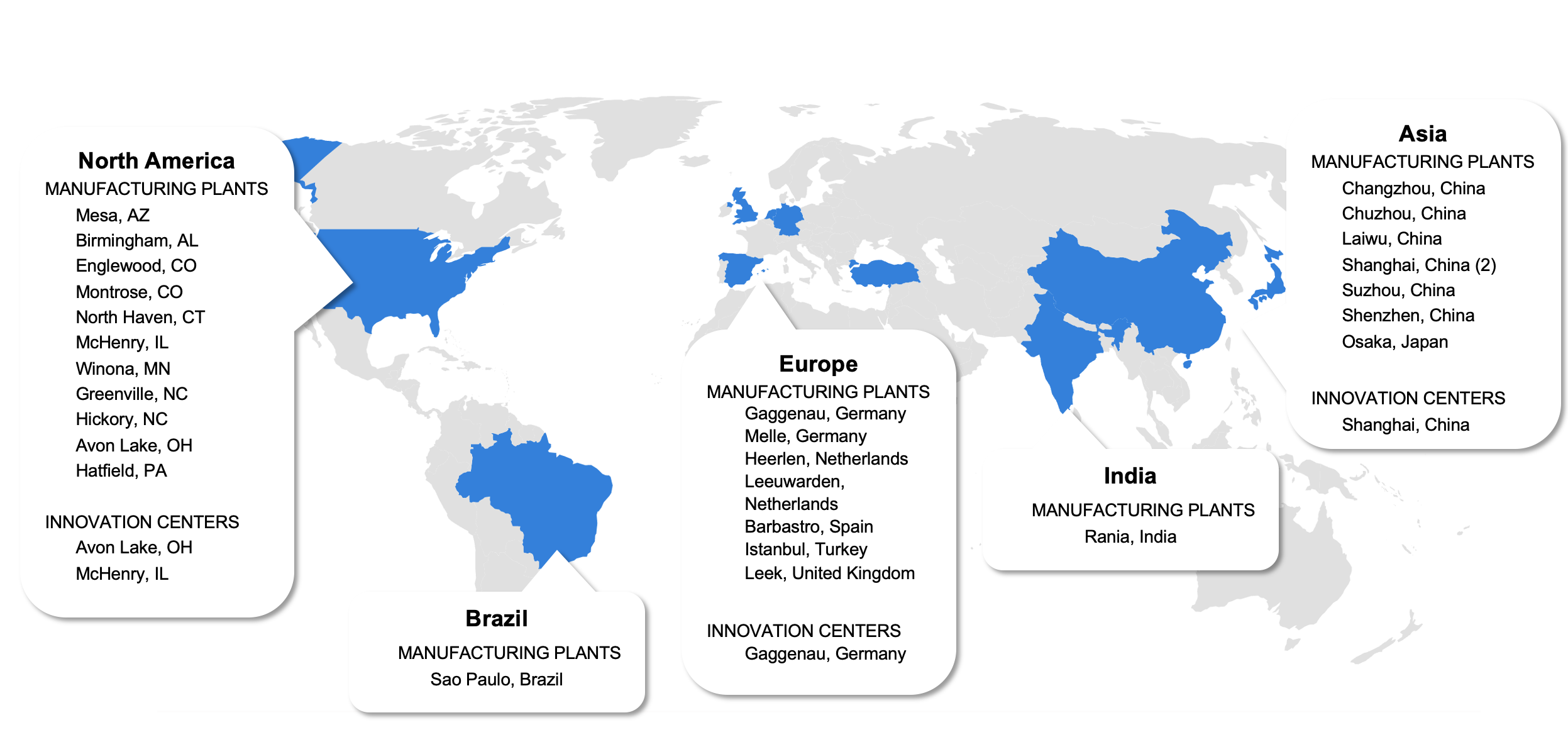

Ensure material consistency with production globally

Due to raw material availability and localized technical support, ensuring the product manufactured in one region is the same as the product manufactured in another can be a challenge. Working with a material supplier that has R&D and technical support globally can help overcome that challenge.

Getting consistency and performance globally encompasses more than material availability. It’s important that the material formulation chosen for a product can be produced accurately across regions. This regional collaboration allows a local source to be identified to manufacture a similar compound with the same quality standards anywhere in the world. Materials suppliers with a robust global footprint can help ensure materials are also backed by localized technical support to help with molding trials or to work through manufacturing challenges anywhere in the world.

Global Locations for Specialty Engineered Materials

3. How can a material supplier help with application goals?

How can a material supplier help with application goals?

The polymer expertise of a material supplier can make a significant difference in the performance, timeline, and processability of your product. Through a process called "application development", plastics engineers and technical service experts work side-by-side with customers as consultants to help connect the dots between material, color, design, and manufacturing.

This process – rooted in advanced design and detailed analysis of the various polymer matrices available, not just those manufactured by the supplier – fosters innovation and expands opportunities for customers to gain market share.

To help a customer make an informed decision based on the unique specifications of an application, a material supplier may use a full suite of industrial, material, component, mold and process design capabilities. Avient’s application development and technical service (ADTS) capabilities include:

Industrial Design

- Research methodologies

- Brainstorming/problem solving

- Concept sketching

- Ergonomic development

- 3D CAD modeling

- Photo rendering & 3D prototyping

- Color, material, & finish selection

- Design for manufacturing

Design Optimization

Prototype Tools

- Consultative review of part, tool or process designs to help improve manufacturing and product outcomes

- Over 10 injection molding machines ranging from 50–550 tons

- Materials sampling and evaluation

- Fully automated continuous fiber reinforced thermoplastic (CFRTP) injection-overmolding cell

- Prototyping combinations of injection molded discontinuous fiber reinforced thermoplastics with CFRTP inserts

- Full suite of auxiliary support equipment including

- Material drying

- Water and hot oil thermolators for mold heating

- Ultrasonic welding for inserts

- Secondary & post operations

- 150-ton compression molding presses

- Profile extrusion

- Co-extrusion film and wire & cable

- Over 20 molds at varying geometries to validate structural, application, and functional performance.

Product Validation Molding with Customer Tooling

- This is the ability to bring customer tooling onsite to conduct trials. This enables the opportunity to evaluate how different materials perform and to establish best-practice processing parameters.

4. What is Computer-Aided Engineering (CAE)?

What is Computer-Aided Engineering (CAE)?

CAE is the use of computer software to simulate real-world application performance in order to evaluate and optimize part design and material selection before investing in equipment.

Mold Filling Simulation

Simulates how melted plastic flows during the injection molding process to validate part design & material solution. Evaluates component design viability with preferred material solution. For fiber reinforced plastics, it will analyze the fiber for orientation and length. It also enables prediction of part quality and manufacturability by determining shrink / warp and weld line location.

Finite Element Analysis (FEA)

Virtually simulates how an application will perform in real-world conditions with a high level of precision. Capable of representing a variety of problems, test methods, models and outputs to evaluate the design, process and material combination for validation or optimization.

Material Datasets Available

A number of material characterization data sets are available in .udb, moldex 3D, and SIMPOE format.

Using CAE to optimize part, tool or process design

Leveraging mold filling simulation, data software, and physical simulation capabilities, can help inform your decision-making process. A material supplier combines its materials, design, and technical expertise to select from a range of solutions to more accurately predict performance and confirm that requirements are being met. In addition to common environmental simulation or functional performance testing services, it can be helpful to conduct individualized testing and simulations in order to optimize material formulations, product performance, or design. By incorporating all the parameters (part design, tool layout, processing requirements, and material selection) there is an opportunity to proactively adjust the gate and runner location and size to ensure quality parts are consistently produced.

5. How can onsite technical support improve product outcomes?

How can onsite technical support improve product outcomes?

Most material suppliers offer technical support, but when working with your supplier, be sure to get clarity on local technical support availability. Onsite expertise adds tremendous value because they can consult on process development, mold design/construction, material training, troubleshooting, and continuous improvement opportunities to ensure product development success.

Equipment Requirements

Based on the material selected, there may be tweaks that can be incorporated to optimize manufacturability. Rely on your supplier to get expert guidance on material handling, drying equipment and sizing needs, as well as primary processing and secondary operations equipment improvement opportunities.

Process optimization

The product development process does not end with design and testing. Take advantage of local technical support and consultation on process development, mold design/construction, material training, troubleshooting, and continuous improvement. This includes material preparation, primary process development, preparation requirements for secondary operations, and tooling debug / optimization.

Polymer Material Handling

Depending on your formulation’s base resin there may be different requirements for storage, preparation, and processing to minimize manufacturing challenges. Ask your material supplier for more information about startup, processing temperatures, shutdown, drying, gate size, gate types, flow rates, purging, regrind, etc. For Avient materials, this information is found in some of our online processing guides.

Troubleshooting

Material processing guides are helpful tools that offer recommendations for common troubleshooting topics. However, Avient’s experienced application development technical service (ADTS) teams can be onsite for first shots off the tool to help develop a process and be available to troubleshoot any defects that may arise.

6. What other challenges are you facing?

What other challenges are you facing?

If you are not sure where to start or have additional questions about your specific application, we have experts available to point you in the right direction. We will take the time to fully understand your needs and goals so we can support you in achieving success. Contact us today to learn more.