FEA – What is it?

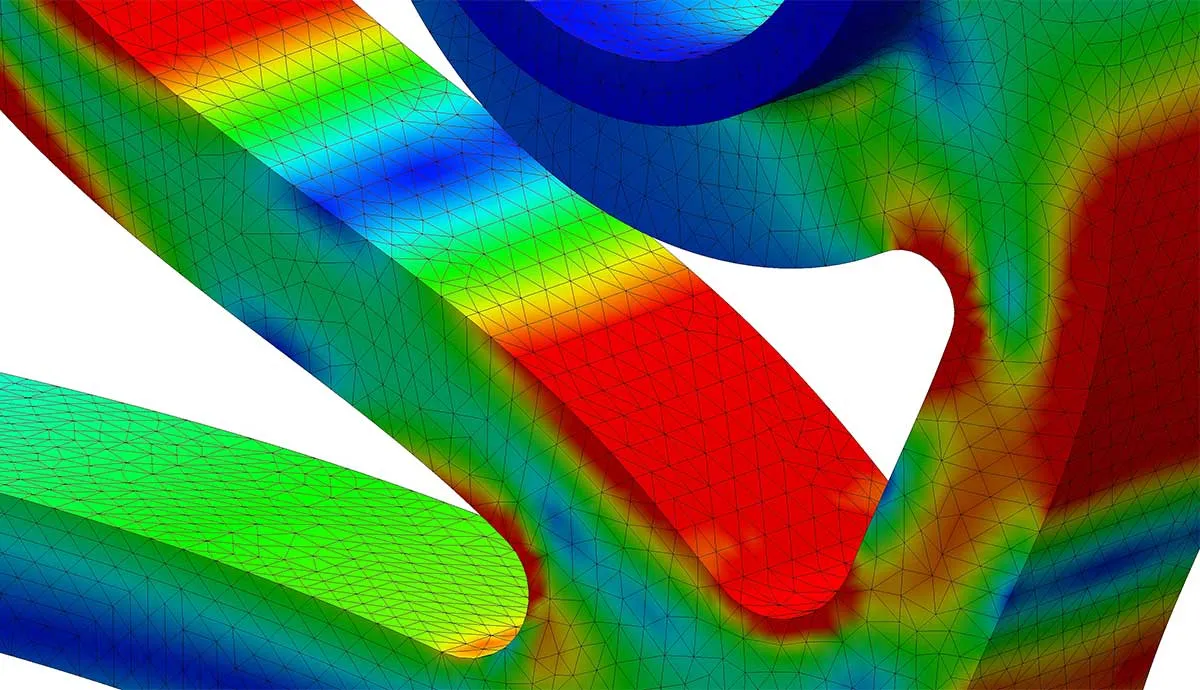

Finite Element Analysis or FEA is a method that virtually simulates a product or process to evaluate its performance and how it might respond to real-world conditions. It solves problems by dividing a large complex system into smaller and simpler ones called elements.

How it Helps

FEA allows for an evaluation of the performance of a design, process, and material combination. With a representative model and a correct interpretation of results, it can achieve high levels of accuracy and can help save significant time and money spent in the new product development process.

FEA Inputs

There are 5 key components that together describe the physical problem and the results to be analyzed:

1. Physics involved

2. Part model (geometry and mesh)

3. Material model (rigid and soft)

4. Load and boundary conditions

5. Desired performance criteria

FEA Outputs

While FEA can represent a variety of problems, the following are typical outputs:

Process analysis also uses FEA methodology to represent the molding process allowing for design, process settings, machine, and tool recommendations. Typical outputs are:

Conclusion

FEA is a powerful aid in the new product development process to validate and refine designs. It can help designers and engineers avoid costly detours and gain confidence in the quality of their process and application.

For a real-world example of how FEA was used to develop protective sports equipment and reduce development time and costs, click here.

Learn more about how FEA can be applied to your application by contacting an expert at Avient today!

Learn more about transforming product development with FEA here.